Why Using Branded Unistrut Matters — and How It Pays Off in Real Projects

When it comes to specifying strut channel for support systems, cable trays, HVAC framing, or rooftop installations, many designers and contractors use “Unistrut” generically. However, there is a significant difference between branded Unistrut (i.e., genuine Unistrut from a trusted manufacturer) and cheaper, unbranded alternatives. Choosing the authentic product brings real advantages — and can make a measurable difference in risk, cost, performance, and long-term reliability.

Here are the key benefits of using branded Unistrut, illustrated with specific use cases and project examples.

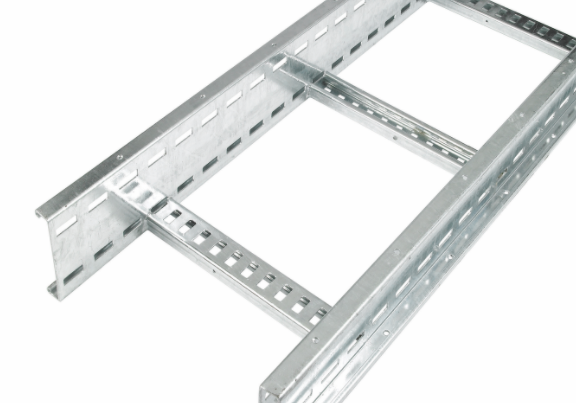

1. Proven Material Quality & Structural Integrity

One of the strongest arguments for specifying branded Unistrut is its consistent material quality. Testing has shown that some unbranded “12-gauge” channels do not actually meet the steel thickness standards.

-

Why this matters: If a structural support channel does not meet its rated gauge, it may deform under load or fail over time. Using genuine Unistrut ensures the strength and tolerances expected in the design.

-

Project example: In a commercial HVAC installation where the channel supports ductwork, even small deflections can lead to vibration, misalignment, or fatigue. Branded Unistrut reduces that risk.

2. Traceability & Accountability

Branded Unistrut products often come with batch markings or serial numbers, which means each component can be traced back to its manufacturer.

-

Why this matters: In critical environments such as hospitals or data centres, being able to trace components is essential for quality assurance, maintenance, and safety.

-

Project example: For a medical equipment support system, one client chose genuine Unistrut rather than generic strut because a failure elsewhere in the facility had been traced to unbranded strut. With branded Unistrut, they could reliably identify the batch and prevent future issues.

3. Superior Finishes & Corrosion Protection

Branded Unistrut manufacturers provide premium coating options. For example, high-performance finishes such as Atkore Defender™ outperform standard hot-dip galvanised strut, thanks to “self-healing” properties.

-

Why this matters: When channel is cut or scratched on site, exposed steel is vulnerable to corrosion. Self-healing finishes help protect the steel and extend the system’s service life.

-

Project example: On a solar-panel rooftop support or telecom installation in a coastal environment, using branded Unistrut with a premium finish reduces early rusting, lowering maintenance requirements and increasing design life.

4. System Compatibility and Design Tools

Using branded Unistrut provides access to a complete engineered system: channels, fittings, brackets, nuts, accessories, and detailed design tools.

-

Application example: Unistrut’s application guides show real-world examples of roof walkways, platforms, and frames, demonstrating how channel, fittings, and grating come together.

-

Engineering support: Design tools allow engineers to calculate point loads, cantilever loads, and moments, ensuring every component is correctly sized.

-

Project example: On a commercial building project, specifying branded Unistrut enabled the M&E team to draw accurately in CAD, ensure all brackets and fittings were compatible, and comply with safety margins.

5. Reusability & Lifecycle Savings

An underappreciated benefit: branded Unistrut is reusable and simple to repurpose. Installation typically involves bolting rather than welding, making disassembly straightforward.

-

Why this matters: It reduces material waste, supports sustainability goals, and saves long-term costs.

-

Project example: When an industrial plant upgraded its equipment, the team reused existing Unistrut frames for new layouts, saving time and money.

6. Demonstrated Real-World Success

Branded Unistrut has been used in high-profile and demanding projects:

-

Design example: The Unistrut P1001 Channel was used in a sculptural installation at a university pavilion competition, supporting a sustainable structure made from repurposed materials.

-

Construction example: In commercial construction, Unistrut modular metal framing systems have been deployed in airports, casinos, and chemical plants, where reliability and traceability are non-negotiable.

7. Safety & Liability Benefits

Branded Unistrut offers higher safety margins and better-published load ratings.

-

Why this matters: Structural failure can have significant cost and safety implications. Using a known, tested product reduces risk.

-

Project example: In industrial environments where secondary steel supports heavy pipework or cable trays, branded Unistrut ensures the support system does not become the weak link.

Conclusion: Branded Unistrut Is Worth Specifying

Choosing branded Unistrut is not just about buying a name — it is about investing in quality, durability, traceability, and long-term value. Whether for rooftop supports, medical systems, industrial construction, or architectural frames, specifying genuine Unistrut helps you:

-

Ensure consistent material strength

-

Access design and engineering tools

-

Benefit from premium corrosion protection finishes

-

Reduce costs through reusability

-

Minimise structural risk and improve safety

For projects where reliability and longevity matter, specifying branded Unistrut is a smart, future-proof decision.