Why Atkore Unistrut’s Defender™ Range Is a Game Changer for Corrosive Environments

When working in demanding and exposed environments, the right choice of finish for your support system can make all the difference. Atkore Unistrut Defender™ offers a premium, high-performance coating that’s tailor-made for harsh, outdoor, and high-corrosion applications.

Here’s a breakdown of what Defender™ is, why it’s so effective and where it makes a real difference.

What Is Atkore Defender™?

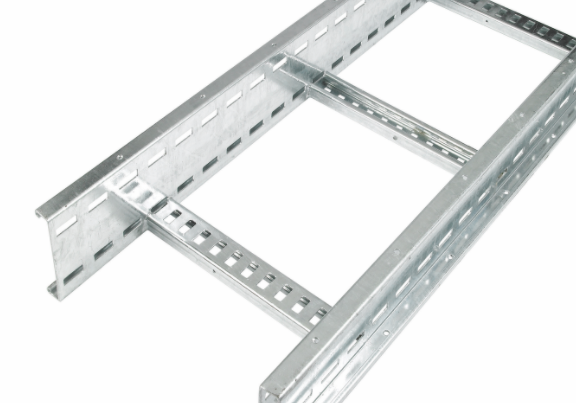

Defender™ is a proprietary finish developed by Atkore for its Unistrut metal framing and cable‑management systems. Rather than relying on traditional galvanising methods, Defender combines two specialised coating layers (meeting ASTM standards A1046 and A1059) to deliver much greater corrosion resistance.

Channels, fittings, and clamps in the Defender range meet rigorous physical requirements (ASTM A1011 SS GR 33), ensuring that you’re using a very robust, high-quality system.

Key Benefits of the Defender Finish

1. Superior Corrosion Resistance

-

Independent lab tests (ASTM B117 salt spray) show that Defender lasts up to three times longer than standard hot-dip galvanised (HDG) finishes before reaching 5% red rust.

-

This makes Defender a great choice for applications exposed to salt spray, humidity, or severe outdoor conditions.

-

Because of its corrosion performance, it often bridges the gap between hot‑dip galvanised and stainless steel — giving very good protection without the high cost of stainless.

2. Self-Healing Coating — Less Rework, More Reliability

One of Defender’s most appealing features is its self-healing property: if you cut or scratch the coating on site, the finish re-propagates into those damaged areas, so you don’t need to go back and paint or touch up.

This delivers several practical advantages:

-

Reduces field labour and onsite painting or patching

-

Cuts down on inspection and maintenance costs over the life of the installation

-

Minimises risk of corrosion forming exactly where the finish is damaged, which is often the weakest point in hot‑dip galvanised systems

3. Easier Installation

-

Defender’s smooth finish helps prevent the binding of threads, which is a common problem when installing in standard hot‑dip galvanised systems.

-

Since there’s no need for extra coating or touch-up, installers can work faster and more cleanly.

-

That streamlines labour and helps keep projects on schedule.

4. Cost-Effective Alternative to Stainless Steel

-

While stainless steel provides very high corrosion resistance, it comes at a significantly higher price. Defender offers much of the performance benefit at a lower cost.

-

Because of its longevity, using Defender can reduce long-term maintenance costs, making it a financially smart choice in the lifecycle of a building.

-

It also helps avoid the premium cost of stainless hardware in many cases.

5. Proven in Real-World, Harsh Applications

Defender is designed specifically for demanding and mission-critical environments:

-

Mobile phone towers, rooftops, solar panel framing, electrical substations, highways, railways, platforms and more.

-

It’s been third‑party tested, with independent lab data supporting its performance.

-

The finish supports a complete system: not just channel, but also fittings, clamps, and accessories — all matched to Defender’s coating.

Things to Be Aware Of

-

Galvanic Corrosion Risk: Atkore advises caution when using Defender-coated parts in contact with stainless steel, due to potential galvanic corrosion.

-

Red Staining: In very aggressive environments, you might observe some superficial red staining over time. Atkore notes that this is not corrosion of the base steel but surface-level oxidation.

-

System Usage: For full benefits, Defender should be used as a complete metal framing system (channel, fittings, clamps) — mixing finishes may reduce performance.

Applications Where Defender Excels ✅

Here are some real-world situations where Atkore Unistrut Defender is especially powerful:

-

Solar Installations: For rooftop racking or ground‑mounted solar systems, Defender resists the elements, giving long-term support without constant maintenance.

-

Telecom Towers: Ideal for cellular masts in coastal or exposed areas, where corrosion is a big concern.

-

Rooftop Mechanical Services: HVAC units, pipework, cable trays – Defender provides durable, low-maintenance framing.

-

Infrastructure Projects: Bridges, rail structures, parking decks – anywhere where steel is exposed and needs protection.

-

Utility / Substations: For outdoor electrical substations and transformers, Defender can help ensure the framing system outlasts more conventional coatings.

Conclusion

Atkore Unistrut Defender™ is a standout innovation in the strut-channel world. Its self-healing, high-performance coating offers three times the corrosion resistance of hot-dip galvanised finishes — without the high cost of stainless steel. It simplifies installation, reduces maintenance, and provides a complete, long-lasting system for harsh environments.

If you’re specifying for a project exposed to rain, salt, humidity, or other corrosive conditions — Defender is a very compelling choice. It balances performance, longevity, and cost much more effectively than many conventional finishes.