Why Hot Dip Galvanised Unistrut Channel Is the Best Balance of Durability and Value

When choosing the right support system for electrical, mechanical, or industrial installations, one of the most important decisions you’ll make is selecting the appropriate finish. For many contractors and engineers, Hot Dip Galvanised (HDG) Unistrut Channel offers the ideal combination of long-term corrosion resistance, durability, and cost-effectiveness.

While pre-galvanised and stainless steel finishes are common alternatives, HDG provides a unique middle ground—offering far superior protection compared to pre-galv and much greater affordability than stainless steel. Below, we explore why Hot Dip Galv Unistrut Channel has become the preferred choice for demanding environments and long-lasting installations.

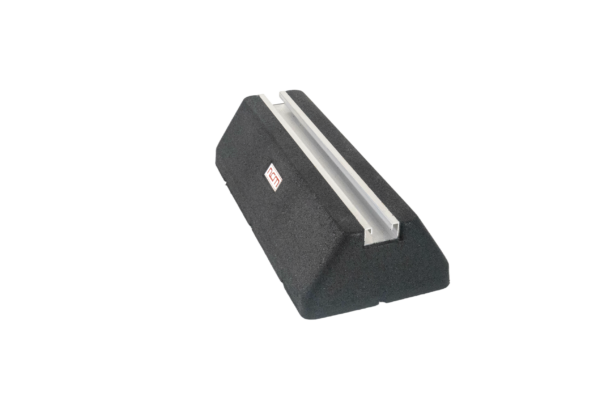

What Is Hot Dip Galvanised Unistrut Channel?

Hot Dip Galvanising is a finishing process where the steel channel is fully submerged in molten zinc. This immersion creates a thick, bonded zinc coating that protects every surface, including edges, corners, and the inside of the channel—areas often left vulnerable with thinner coatings.

The result is a rugged, highly corrosion-resistant Unistrut Channel designed to perform reliably even in harsh conditions.

The Benefits of Hot Dip Galvanised Unistrut Channel

1. Superior Corrosion Resistance Compared to Pre-Galvanised

While pre-galvanised (or “pre-galv”) channel is coated as a flat steel sheet before forming, HDG undergoes full post-fabrication immersion. This key difference gives HDG several major advantages:

-

Thicker zinc coating for longer-lasting protection

-

Complete coverage, even at bends and cut edges

-

Better performance in outdoor and industrial environments

-

Significantly slower rate of corrosion

In real-world conditions, Hot Dip Galv often lasts several times longer than pre-galv, making it the smarter choice for installations exposed to moisture, chemicals, or fluctuating weather.

2. More Affordable Than Stainless Steel—Without Sacrificing Reliability

Stainless steel provides exceptional corrosion resistance, but its higher material cost makes it impractical for many projects. Hot Dip Galv fills the gap by offering:

-

Impressive longevity at a fraction of the cost

-

Strong resistance to rust and environmental wear

-

Excellent performance in most outdoor applications

For installations that don’t require the premium protection of stainless steel—such as mild marine exposure, general outdoor use, or industrial environments—HDG delivers outstanding durability while keeping budgets manageable.

3. Ideal for Tough, Real-World Environments

Hot Dip Galvanised Unistrut Channel performs exceptionally well in:

-

Outdoor construction

-

Utility and electrical infrastructure

-

Water and wastewater treatment plants

-

Agricultural and food processing facilities

-

Chemical and industrial plants

Its rugged zinc coating withstands moisture, temperature changes, and abrasive conditions far better than lighter coatings.

4. Long-Term Performance with Minimal Maintenance

Because the zinc layer is metallurgically bonded to the steel, it wears away very slowly, offering decades of protection. Unlike painted or electroplated finishes, HDG doesn’t peel, flake, or require frequent recoating.

This makes Hot Dip Galv Unistrut a low-maintenance, high-value solution for long-term installations.

Conclusion: The Smart Choice for Cost-Effective Corrosion Protection

Hot Dip Galvanised Unistrut Channel provides an unbeatable balance between corrosion protection, longevity, and affordability. It offers dramatically better resistance than pre-galvanised finishes, ensuring reliable performance in outdoor and industrial environments. At the same time, it remains far more economical than stainless steel—without compromising on durability.

If you’re seeking a strong, long-lasting, and budget-friendly framing solution, Hot Dip Galv Unistrut Channel is the clear choice.